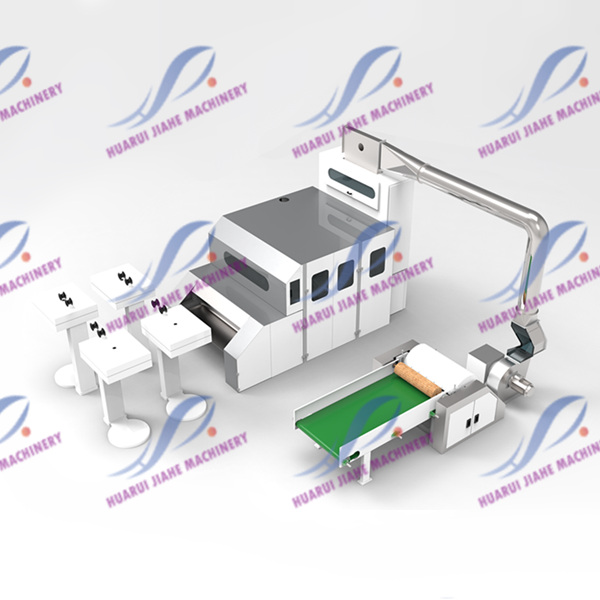

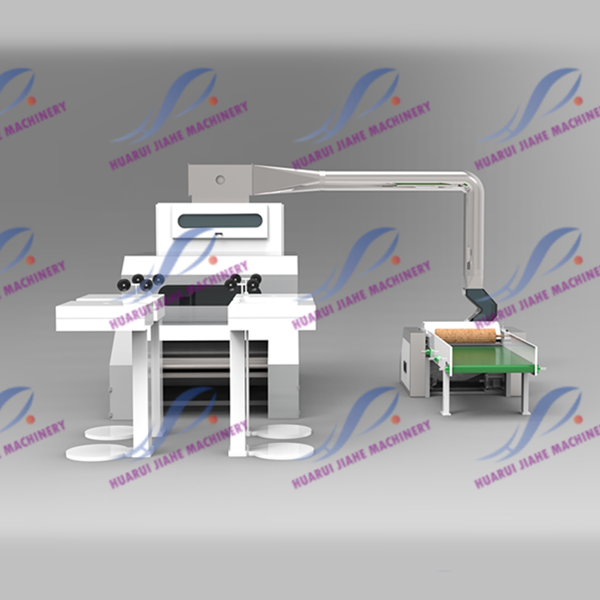

Cotton Sliver Production Line

Specification, working principle :

Opening machine– Feeding machine– Carding machine

Uses: used in carding cotton swabs, cotton balls, medical cotton, cotton production

Features: cotton after opened into the auto chute feeder, evenly fed into carding machine by auto chute feeder, 1-4 coiler can be chosen, the sliver can be minimum of 1.5 g / m.

Opening machine:

1. Feeding form: man hand feeding by feeding conveyor curtain ( can be equipped with dust cage )

2. Machine width: 1000mm ( cylinder width )

3. Doffer transfer stripping: needle / thugs

4. Oversize: 3400X1600X1200 (MM)

5. Main motor ( cylinder / doffer ) 95Kw, fan 4kw

PS: Total height of machine assembly is 3460mm

Carding machine:

1. Application: Used for processing 100% cotton and man-made fibers or blends, lap feeding.

2. Sliver count (g/m):3.5-6.5

3. Production: Up to 35kg/h

4. Working width: 1000mm

5. Attached carding segment: A group of licker-in carding segments Two rear stationary flats/ Three front stationary flats

6. Total draft: 67-120

7. Licker-in dia.(mm):Φ250

8. Lick-in speed (RPM): cotton/1070;man made fiber/980

9. Cylinder dia. (mm):Φ1289

10. Cylinder speed (RPM): cotton/360; man made fiber/330

11. Doffer dia. (mm):Φ706

12. Doffer speed (rpm):21.3-38.2

13. Number of flats (working total): 40/106

14. Flats speed (mm.min):cotton177,214,266 man-made fiber/81,98,122

15. Can size (dia. ×Height): Φ600×900mm/Φ600×1100

16. Suction: Three suction points- triangular space between Doffer and Cylinder, licker-in cover and under-card lattice

17. Air volume (continuously):1300m³/h

18. Air pressure: 500-600Pa

20. Main motor:3.3kw

21. Doffer-driving motor:1.1kw(Inver.digital display are optional)

22. Blower motor: 0.06kw

23. Space (L×W):3809×2092mm

24. Machine weight: Approx.4500kg