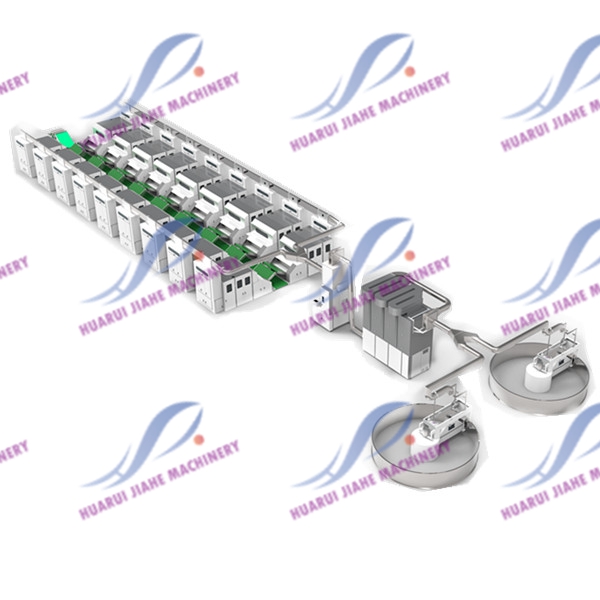

Big Cotton Roll Production Line With Straight Laying

Product Display

1. Opening machine

Application

The cotton will be pre opened by this machine, and the cotton will be blowed into the feeding machine.

Specification

(1) Dimension:6000×1800×1200mm;

(2) Working width:1000mm;

(3) Capacity:180-280kg/h;

(4) Opening type: wooden plate with needle

(5) Opening roller speed:880r/min;

(6) Installed power:10.25kw.

- Chute feeder

Application

The chute feeder include 12 rows of needle plate opening rollers, which can have quite small cotton clusters at low speed, With the independent circulation fan, the uniform cotton layer can be produced. At the same time, each chute feeder is equipped with a continuous feeding control system to automatically adjust the cotton supply.

Specification

Capacity:10-100kg/hr

Power:1.32kw

Dimension(L*W*H):600×1352×1800mm

Working width:940mm

- Carding machine for roll type

Application

This machine is mainly used for processing cotton fiber and chemical fiber. The cotton layer sent by the previous process is opened and combed to remove impurities, so that all the curly and blocky cotton balls become the basic straight single fiber state. In this process, remove seeds, impurities and short fibers left,then the net is formed for the use of the next process.

Technical Specifications:

1) Applications: for processing cotton and chemical fibers or blends in length 22-76mm,fed with lap

2) Machine weght: Approx4300kg

3) Production: Up to 40kg/h

4) Working width: 1000mm

5) Attached carding segment: a group of licker-in carding segment rear stationary flats front stationary flats

6) Licker-in diameter: 250mm

7) Licker-in speed: cotton 1070r/min chemical fiber 980r/min

8) Cylinder speed: cotton 360r/min chemical fiber 330r/min

9) Doffer diameter: 706mm

10)Doffer speed: 21.3-38.2r/min

11)Number of flats(working/total):40/106

12)Flat speed: cotton 177 214 266mm/min chemical fibers 81 98 122mm/min

13)Space requirement (L*W): 3809mm*2092mm

14)Suction: three suction parts: triangle space between cylinder and doffer, cover of licker-in, lattice feeding part under card

15)Air volume(continuously) 1300cbm/h

16)Air pressure: -500~-600P

17)Total installed power: 4.8kw

18)Motor for main dirve: 3.3kw

19)Doffer-driving motor: 1.5kw(Frequency Converter Motor is optional)

4, Straight laying

Parameters Detail :

Working width: 900-1000MM

Capacity : 250-320KG/H (according to quantity of carding machine )

GSM: 80-200

5, Cutting and rolling machine

Application

This machine is used for non-woven production line, to product into the required width and length for packaging

Technical data

Work width:1800mm

Dimension:2900*1600*880mm

Knife motor:0.55kw, main motor: 1.1kw

Speed:1-15m/nin

Diameter of roller: 320mm